Non destructive testing

GEO Logica deals with tests, surveys and monitoring of architectural heritage aimed at control and diagnostics

The analysis of a building structures (walls, foundations, etc.) is crucial in the assessment of its stability and structural deterioration.

Controls on buildings structures, performed with non-destructive and/or moderately destructive techniques, such as radar surveys, sonic and ultrasonic surveys, thermographic and endoscopic investigations, flat jacks, mechanical characterization tests, etc., are the basis for the knowledge of their conditions, for the designing and planning of their conservation and for the development of architectural and archaeological heritage.

We use high-tech tests and monitoring equipment and we give special care to their maintenance and certification as well as to the training and qualification of the personnel operating on site.

Our technicians are II level R.I.N.A. certified, in accordance with the ISO 9712 quality system.

Sonic and Ultrasonic Investigations

Sonic and ultrasonic investigations, non-destructive tests, consist of measuring the transit time between two points, of a wall or a structural element, of a shock wave generated by a mechanical impulse.

The speed of the waves, in walls or structures, is related to the quality of the material that composes them, being higher in walls or structures with better mechanical characteristics and vice versa or the presence of continuity solutions within them.

The investigations can be carried out both in “direct transparency” mode and therefore placing the probe receiving the mechanical impulse on the opposite side of the structure investigated with respect to the point of source of the impulse, and in “surface” mode, i.e. with a transmitter and receiver on the same side of the structure or wall surface or in “semi-transparency”, in the case in which the transmitter and receiver are placed on surfaces in orthogonal contact with each other.

Remote Monitoring

The structural conditions of the buildings (presence and dynamics of fractures, movements and shifts from the vertical) are monitored by us continuously and for very long periods (up to several years) by means of sensors and inclinometers placed on the points of interest with data transmission collected in real time for immediate processing. In this case it is also possible to set alarm levels which can help in preventing damage to people.

In addition to the displacement and verticality sensors, the system is able to manage the monitoring of various parameters such as temperature, humidity, etc.

Flat jacks

The test with flat jacks, a limited invasive test, can be performed in two ways: single and double jack; in the first case the state of stress of the masonry at the measurement point is measured, while in the second the deformability and resistance characteristics are also determined.

The single jack test consists of inserting a flat jack into a crack made in the masonry and making it expand until the masonry is brought back to the tension conditions prior to cutting the crack, measuring the necessary effort.

In the double jack test, the deformations produced in the portion of masonry between two flat jacks are measured as a result of increases in pressure (load); The modulus of elasticity of the masonry is thus obtained as the ratio between the increase in pressure and the deformation produced.

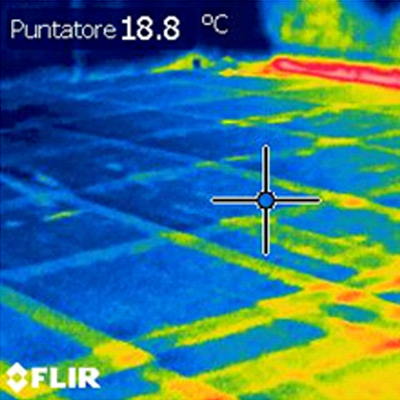

Thermography

Thermographic analyzes of masonry structures, also non-destructive analyzes based on the taking of infrared images, allow an evaluation of anomalies and characteristics of masonry that cannot be identified in the visible wavelength range.

The use of the method ranges from the search for points with humidity infiltrations in the walls, solutions of continuity and texture of the walls present beneath the plasters and up to the energy efficiency certifications of the buildings.

Georadar

The G.P.R. investigation (Ground Penetrating Radar) is a non-destructive geophysical diagnostic technique, which allows you to obtain images of two-dimensional or three-dimensional sections of the ground and/or structures investigated for a depth that depends on the type of materials and the type of sensor used.

The ground penetrating radar method is based on the generation of high frequency impulsive waves (generally between 25 and 2000 MHz) which can be introduced into the body to be investigated with an appropriate (transmitting) antenna. The measured parameter is the propagation time of the wave which, upon encountering obstacles or discontinuities, returns to the surface and is picked up by the (receiving) antenna as a reflected echo.

Images are obtained that represent the sections or volumes traveled by the mobile antenna on the investigated surface.

The areas of application of the GPR methodology can generally be identified as: environmental prospecting, geotechnical investigations, architectural studies, archaeological research, search for underground services, structural monitoring, identification of cavities and hidden objects.

Sclerometric tests

The sclerometer tests are carried out with the sclerometer, or Schmidt hammer, which consists of a striking mass which counteracts, by means of a spring, a percussion rod placed in contact with the surface to be analysed.

The test must be carried out on structures without irons or finishes such as plaster, floors, etc.; Areas with gravel nests, scratches, high porosity must be avoided and the sclerometer axis must be perfectly orthogonal to the surface to be investigated.

The test results are qualitative and give indications on the mechanical characteristics of the material investigated.

Pachometric tests

Pachometric investigations are carried out to detect the position of the iron reinforcement inside the concrete structures and to give an estimate of their diameters; Pachometry is also used to identify areas without irons where sclerometric, ultrasonic or pull-out investigations can be carried out.

The Pacometer consists of a magnetic field emitting probe, connected to a digital processing unit, which is slid over the surface to be investigated. The variations in the magnetic field generated by it allow us to determine with good approximation, in addition to the position, also the thickness of the concrete cover and the diameter of the irons present.

Mortar investigations

The mortars, especially the “historic” mortars, are sampled to be subjected to both chemical-mineralogical and physical-mechanical analyses.

The purpose of the analyzes to which the mortars are subjected responds to two aspects of their nature: that of a structural component of the walls and that of a characterizing element of the construction technique and the period of construction of the building.

Clearly, a clear and unambiguous characterization of the chemical-mineralogical and physical-mechanical data allows, in the case of buildings with historical value, a non-negative impact on their recovery and restoration.

Core drilling

Core drilling on concrete structures or masonry is carried out mainly for the sampling of portions to be subjected to compression tests in the laboratory.

They can also be carried out, especially for non-concrete walls, to have a direct view of the characteristics and types of materials used, or to collect samples (primarily mortars) to be subjected to chemical-mineralogical or granulometric analyses.

The Pacometer consists of a magnetic field emitting probe, connected to a digital processing unit, which is slid over the surface to be investigated. The variations in the magnetic field generated by it allow us to determine with good approximation, in addition to the position, also the thickness of the concrete cover and the diameter of the irons present.

Load tests

Load tests, non-destructive tests, are carried out to evaluate the resistance and elastic response of the horizontal structures of a building, generally floors.

The test involves the measurement, using sensors, of the displacements produced by load increases applied using tanks to be filled with water.

The test, in the case of testing of buildings, is carried out to verify whether there is correspondence between the behavior theoretically evaluated for the structures investigated and their actual behavior following loading.

Pull Out Tests

The “Pull-Out” test is a non-destructive test which consists in evaluating the compressive strength of the concrete by correlating it with the force necessary to extract a standard metal expansion plug, inserted into it, by means of a hydraulic jack.

The test must be carried out on portions of the structure without reinforcing bars.

Pull Off tests

The “Pull-Off” test is a semi-destructive investigation (it causes limited damage to the test sample), which consists in the measurement of the direct tensile strength of injection mortars, mortars, concretes and surface protection systems (SPS) , used for the protection and repair of concrete.

The test method consists in exerting direct traction on a steel tablet made to adhere to the surface of the material to be tested having defined the test area obtained by core drilling on the surface of the sample.

Videoendoscopies

Video inspection, or endoscopy, of wall structures allows a direct evaluation of the characteristics of their internal portions with a non-destructive approach thanks to the limited invasiveness of the investigation.

In fact, the investigation involves the taking and analysis of images of the structures, through existing fractures or holes produced (φ = 20 mm), with micro-cameras or endoscopes.

Tests on armor irons

The reinforcing bars can be tested through laboratory tests and on-site tests. For the first type of tests, the bars are taken and subsequently subjected to chemical, physical or mechanical tests in a material testing laboratory. Steel bars are expected to be taken from areas of low stress and the extraction must cause as little disturbance as possible to the constituent elements of the reinforced structure.

On site it is possible to test the corrosion of the reinforcement rods by means of potential mapping. The technique is non-destructive and is based on an electrochemical method. It involves measuring the potential of the reinforcements through a reference electrode, placed on the surface of the concrete using a damp sponge to ensure electrolytic contact.

Corrosion of the reinforcements immersed in the concrete is usually negligible, however, the thin protective oxide barrier on the irons, which ensures natural protection of the steel, can be destroyed, with the consequent triggering of corrosive processes. The diagnosis of the state of corrosion of the reinforcements allows us to intervene promptly on them and according to adequate restoration methods.

Windsor Tests

The resistance of mortars or concretes can be assessed on site by using a special Windsor penetrometer. It is a semi-destructive mechanical technique based on the measurement of the resistance to penetration of a steel pin (or pin) inserted into the medium to be tested by a special probe or penetrometer having predetermined insertion energy.

Operationally, after having inserted the pin, measure the portion of it that failed to penetrate inside the medium and, using correlation curves, obtain the compressive strength of the portion under investigation.

Carbonation tests

The carbonation test is a semi-destructive investigation technique, which aims to measure the depth of carbonation of the surface layer of a concrete structure.

Operationally, the sample or section to be tested is immersed in a phenolphthalein solution (with 1% ethyl alcohol), which causes a purple color in the area not affected by carbonation. The carbonated (colorless) section is measured, in which corrosion phenomena of the reinforcing irons can occur.

Vibration monitoring of buildings and civil structures

The vibrations induced in a building can cause various effects including: disturbance for the occupants of the buildings, reduction of their operational efficiency, and structural or architectural damage to the buildings themselves. It is therefore necessary to control the dynamic and vibrational behavior of buildings over time.

Operationally, the installation of accelerometers connected to acquisition systems is carried out. Each acquisition unit is calibrated with a minimum threshold depending on the impulse to be monitored and a sampling time compatible with the natural frequency is established, estimated in the theoretical phase for the structural element under examination.